Torque limiters can also be called torque limiters, torque couplings, safety couplings, and mechanical clutches. According to the structure, it is mainly divided into friction type torque limiter and ball type torque limiter.

Friction type torque limiter protection principle

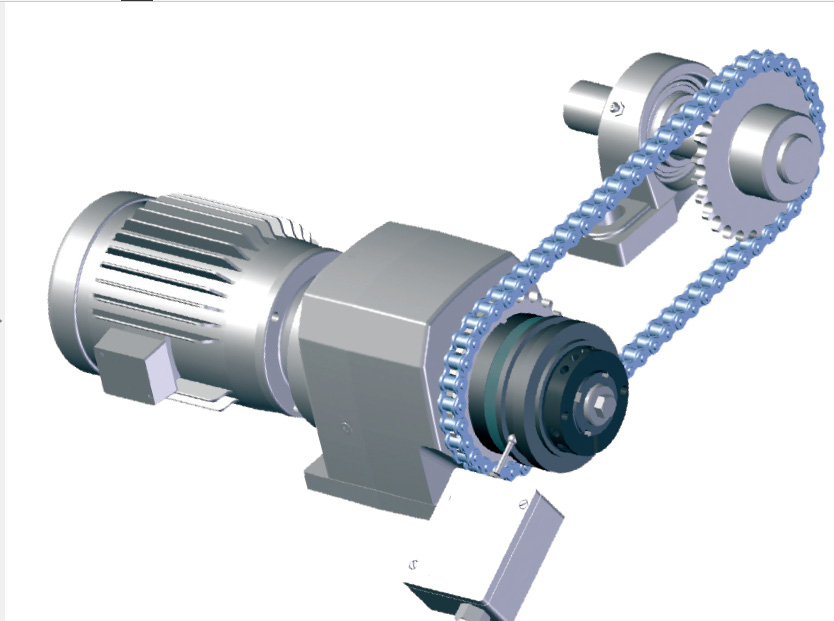

The friction type torque limiter uses a lock nut to make the spring generate elastic force, which acts on the friction plate. The sprocket and other wheel objects are sandwiched between the two friction plates. Due to the elastic force, friction occurs between the friction plate and the sprocket. Force, so that torque can be transmitted.

When the equipment is overloaded, relative sliding occurs between the sprocket and the friction plate, but the torque during slippage is still maintained between the two (there is still torque transmission, but the drive end cannot be driven), and the driving end is idling at this time. The transmission end stops.

After eliminating the overload, the torque limiter will automatically reset.

Working principle of steel ball torque limiter

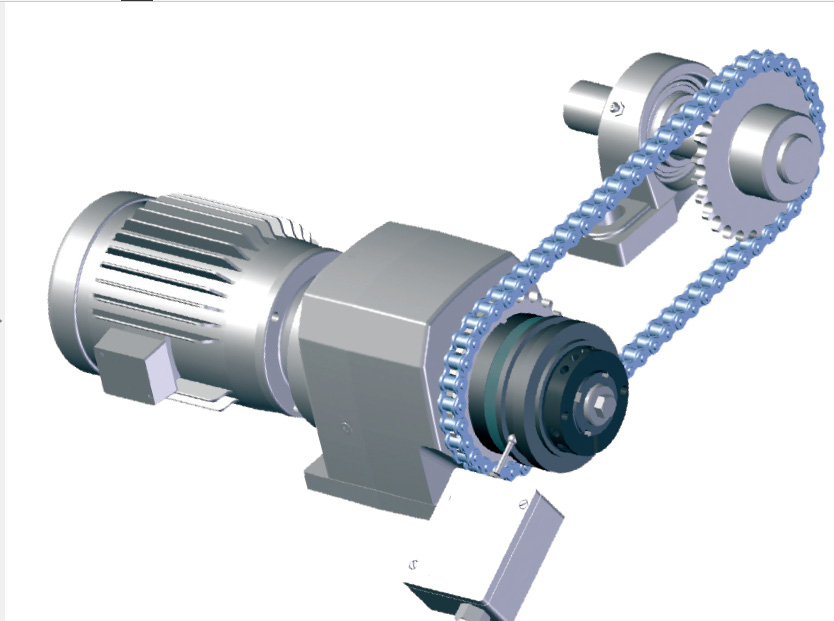

The critical torque is controlled by a precision spring, which can reach a very precise torque value. For the same size product, different built-in springs can be replaced to determine different slipping torques. It is used for installation with a shaft at one end and a transmission at the other end, or according to customer requirements Equipped with couplings to facilitate customer shaft-to-shaft linking.

When the equipment is overloaded, the transmission end will stop first, and the active end will run idly. However, in the moment of overload, the torsion limiter can be axially displaced to give a displacement, and a proximity switch to detect this displacement can give a signal. Output, alarm or stop the motor motor to achieve complete automation.

After eliminating the overload, the reset method is the only position in a circle (or multiple points as required).